Ladybridge High School – Dcecarbonisation Project

Client

Robertson Facilities ManagementLocation

BoltonSector

EducationRequirements

Plantroom upgradeObjective

Reduction in carbon footprint

We were awarded the contract to carryout all M&E works required for the decarbonisation project at the school.

There were many aspects to this project which made strong design, planning, and project management critical to successful delivery if we were to complete on time:

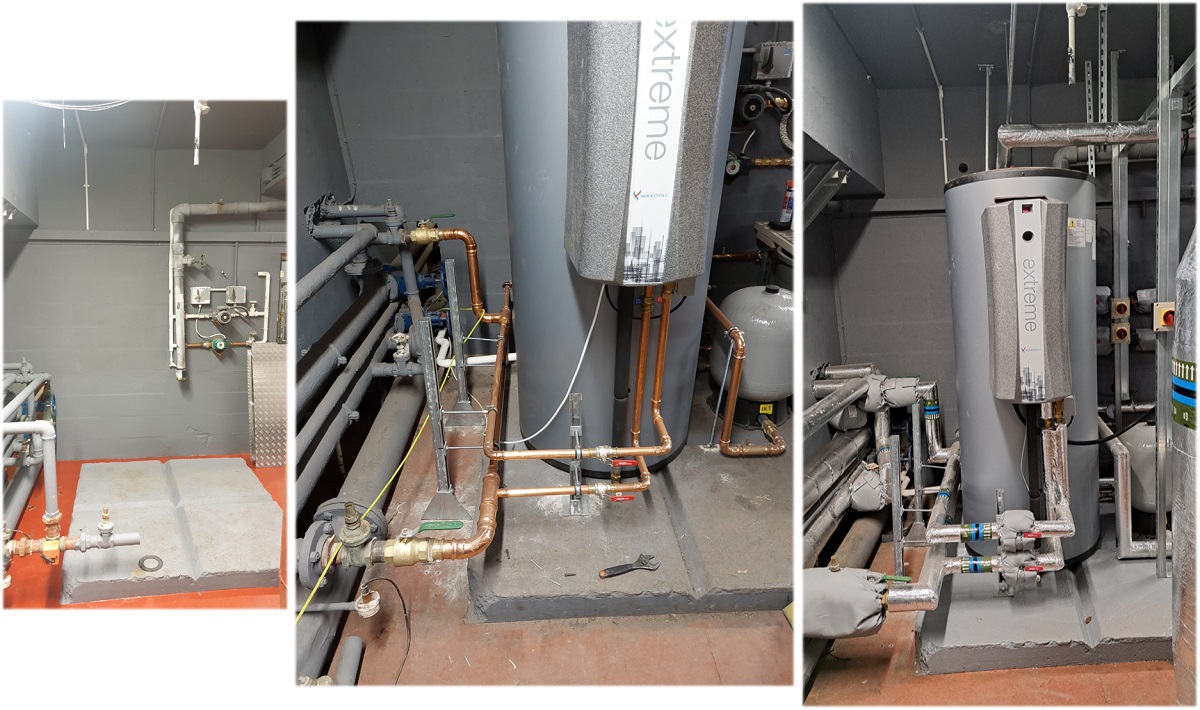

Air Source Heat Pumps

A significant part of this project was the installation of three 128kW ashp’s (totalling 384kW) whose purpose is to move the school away from gas-fired plant.

Buffer Vessels

The ashp’s will pre-heat 9000ltrs of water in three buffer vessels which will then circulate to the school’s heating system and swimming pool heating.

Heat Recovery Units

Four air handling units were replaced with highly energy efficient heat recovery units, along with all modifications to the ventilation ductwork; these units will supply warm air to the toilets, changing rooms and lounge/bar areas.

Pump Replacement

All pumps in the plantroom have been replaced with energy efficient inverter driven units, with pipework modifications completed as required.

Domestic Hot Water Unit

The DHW provision was upgraded to realise energy savings whilst delivering more hot water.

Controls

The controls have been upgraded to realise the benefits of energy efficient control strategies.

These controls also offer the benefit of remote monitoring, alarms, and reporting.

Swimming Pool Heat Exchanger

A failing heat exchanger supplying the swimming pool has been replaced with a high efficiency unit.

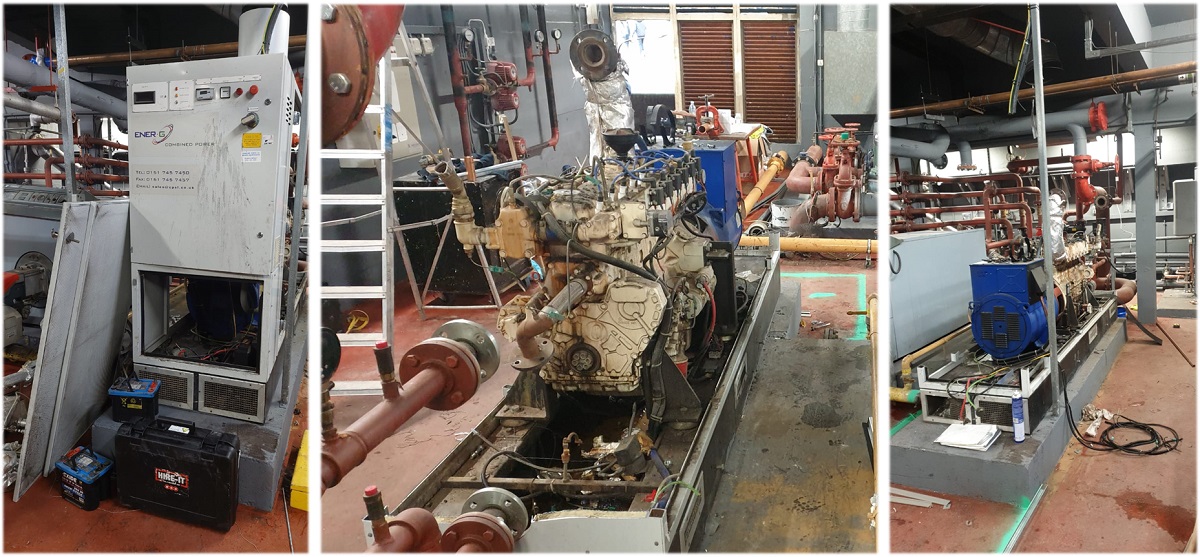

Combind Heat & Power Unit

During the installation works, we also removed a redundant CHP unit.